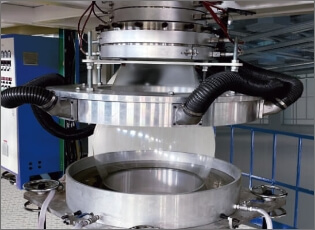

Horng Tair Launching 9 Layer Blown Film Extrusion Die Head

< Excerpt from Economic Daily >

Its quality is comparable to that of advanced countries such as Germany, Italy, and Japan, and is highly recognized by the market. To react to the market's definite need for high-end packaging materials, we were the first in Taiwan to launch a nine-layer extrusion blown film die, which not only reduces product waste and costs, but also improves safety and protection function of film. It complies with EU non-toxic environmental standards and passed(RoHS2011/65/EU) green environmental product certification.

Horng Tair Industrial Corp. stated that when producing high-barrier films for food, vinyl alcohol copolymer(EVOH) and polyamide(PA) or polyethylene(PE) layers are usually combined through an adhesive layer –also called as tie layer- to achieve the required performance. As the market's requirements for oxygen and odor barrier properties, environmental resistance, preservation, freshness preservation, UV protection and other functions of packaging materials continue to increase, in order to provide these, the demands of high barrier films continue to expand, especially in food packaging. This is remarkably evident in beverages, medical care, and pharmaceuticals industries. Not only is the prospect promising, a lot of factory has already improve their production capacity and profit margins with multilayer blown film line, especially 7 and 9 layer blown film lines. Currently, 7 layer blown film machine technology has been already very mature, and the 9 layer blown film machine represents more advanced technology. Thanks to its solid R&D team, Horng Tair Industrial Corporation was able to take the lead in developing 9 layer blown film die head.

Horng Tair Industrial's nine-layer die adopts a conical stack design, which increases the number of layers in the production line and at the same time maintain high output. HT 9 layer blown film extrusion die head realize customer’s main demand, thinner layer for expensive barrier property materials and tie layer. Thereby the customers can reduce costs and develop new products, with a maximum barrier film production capacity of 400kg/h. Due to the increase in output and film quality, the investment in a nine-layer film production line is expected to recover within the earning of one year.