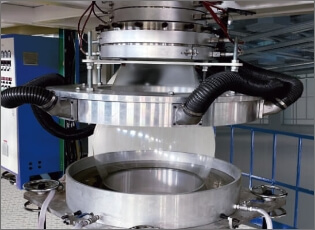

Horng Tair Die Head

At the core of every Horng Tair Group’s multi-layer blown film production line, there is our breakthrough Horng Tair Die Head mold technology. With years of manufacturing and design experience combined with precise calculations from simulation analysis, Horng Tair has achieved industry-leading film transparency and strength.

Regardless of the product type or number of layers, Horng Tair Die Head ensures optimal flow channel efficiency. Horng Tair excels in high output production and has special insights into both symmetrical and asymmetrical films.