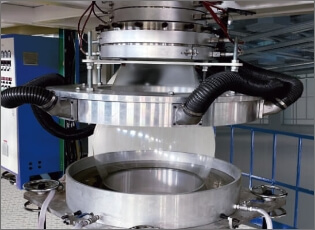

HT Customized Extrusion Unit

The HT professional R&D team is committed to designing customized extruders that help clients achieve their production goals while increasing profit. These extruders maintain constant torque across a wide range of speed and use different surface treatment technologies depending on the raw material to significantly reduce wear, extending the machine’s lifespan and lowering maintenance costs.

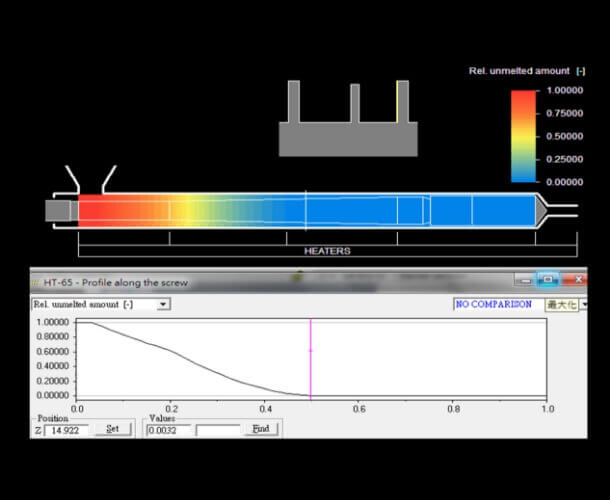

High-Performance Barrier Screw Design: Superior Melt Uniformity and Pressure Stability

HT extruders are equipped with a low shear rate, high-performance barrier screw design, achieving optimal melt uniformity at low temperatures while effectively controlling pressure fluctuations. This design ensures an ideal balance between output and quality for various materials, giving films the ideal optical and mechanical properties to meet high-quality application requirements.

Diverse Specifications of Extruder and Flexible Production Configurations

HT extruders offer multiple diameter options, ranging from 25 to 150 mm, to meet different layer proportion and production capacity demands. They can be customized for 1 to 9 layers of film production, so that clients are able to deal with diverse multilayer film manufacturing requirements.

Precise Structure Design: Low Noise, Low Vibration, and Space Efficiency

HT extruders feature precise low-noise and low-vibration design to ensure smooth and reliable operation. Moreover, adopting a compact U-shaped structure makes these extruders ideal for facilities with limited floor space.

The HT customized extruders combine high performance, durability, and operational flexibility. They are designed for modern film production needs, making them an ideal choice for businesses to boost productivity, reduce maintenance costs, and achieve higher production efficiency.

High-Performance Barrier Screw Design: Superior Melt Uniformity and Pressure Stability

HT extruders are equipped with a low shear rate, high-performance barrier screw design, achieving optimal melt uniformity at low temperatures while effectively controlling pressure fluctuations. This design ensures an ideal balance between output and quality for various materials, giving films the ideal optical and mechanical properties to meet high-quality application requirements.

Diverse Specifications of Extruder and Flexible Production Configurations

HT extruders offer multiple diameter options, ranging from 25 to 150 mm, to meet different layer proportion and production capacity demands. They can be customized for 1 to 9 layers of film production, so that clients are able to deal with diverse multilayer film manufacturing requirements.

Precise Structure Design: Low Noise, Low Vibration, and Space Efficiency

HT extruders feature precise low-noise and low-vibration design to ensure smooth and reliable operation. Moreover, adopting a compact U-shaped structure makes these extruders ideal for facilities with limited floor space.

The HT customized extruders combine high performance, durability, and operational flexibility. They are designed for modern film production needs, making them an ideal choice for businesses to boost productivity, reduce maintenance costs, and achieve higher production efficiency.

Inquiry Form

Find HT representatives of your region

Fields marked with an asterisk * are required.