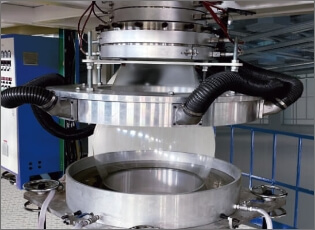

HT Customized Film Winding Unit

HT takes user experience as the foundation of its blown film extrusion equipment design, using years of accumulated experience to develop unique insights to wind special materials or specific thicknesses and widths of film. By providing customized winding solutions tailored to diverse customer needs, HT enhances production efficiency and convenience, ensuring the quality and flatness of film rolls.

The modular structure design increases equipment flexibility and product diversity. HT also adopts advanced safety standards, equipping multiple safety protection systems such as emergency stop buttons and overload protection to ensure safety of operators.

Automation Options

Automatic Roll Change: When a roll is fully wound, the automatic roll changing system will switch to a new core for winding. Additionally, an optional mechanism of automatic releasing of completed film roll also can be added, reducing dependency on operators and increasing production efficiency.

Automatic Tension Control: This feature automatically adjusts the tension based on film thickness and line speed, ensuring stable tension during winding to prevent film over-stretching or loosening due to tension fluctuations.

Human-Machine Interface (HMI): A user-friendly touchscreen interface allows operators to easily monitor and adjust winding parameters in real-time, enhancing production convenience and reliability.

Automatic Core Loading System: This automation system further reduces manual operation risk and costs, so that can minimize material waste caused by operational errors.

These features are indispensable in modern blown film plant, to improve blown film quality, reduce waste of raw materials, and enhance overall production efficiency.

Gap Winding

The Sid Freedom Series 3-in-1 film winder is designed to meet the needs of films with various thicknesses, enhancing blown film production flexibility and product diversity to satisfy modern blown film demands for multi-functionality and high quality. This winder adopts an innovative gap design to precisely control the distance between the film and the core, ensuring stable, high-quality winding across different film thicknesses.

Applicable to Wide Range of Film Thickness :

For extra-thick films, the gap prevents slippage, ensuring film winding quality. On the other hand, for thinner films it avoids excessive compression, maintaining product integrity and uniformity. This feature makes the Sid Freedom Series an ideal choice in the market demanding film with the wide range of thickness.

Precision Control for Enhanced Quality :

The Sid Freedom Series is equipped with a high-precision control system that ensures winding stability and consistent tension, preventing film misalignment or deformation. Regardless of film thickness, the system guarantees stable tension and winding quality, furthermore, improves product consistency. Thanks to these features, the Sid Freedom Series stand out from multifunctional and high-precision film winding market.

The modular structure design increases equipment flexibility and product diversity. HT also adopts advanced safety standards, equipping multiple safety protection systems such as emergency stop buttons and overload protection to ensure safety of operators.

Automation Options

Automatic Roll Change: When a roll is fully wound, the automatic roll changing system will switch to a new core for winding. Additionally, an optional mechanism of automatic releasing of completed film roll also can be added, reducing dependency on operators and increasing production efficiency.

Automatic Tension Control: This feature automatically adjusts the tension based on film thickness and line speed, ensuring stable tension during winding to prevent film over-stretching or loosening due to tension fluctuations.

Human-Machine Interface (HMI): A user-friendly touchscreen interface allows operators to easily monitor and adjust winding parameters in real-time, enhancing production convenience and reliability.

Automatic Core Loading System: This automation system further reduces manual operation risk and costs, so that can minimize material waste caused by operational errors.

These features are indispensable in modern blown film plant, to improve blown film quality, reduce waste of raw materials, and enhance overall production efficiency.

Gap Winding

The Sid Freedom Series 3-in-1 film winder is designed to meet the needs of films with various thicknesses, enhancing blown film production flexibility and product diversity to satisfy modern blown film demands for multi-functionality and high quality. This winder adopts an innovative gap design to precisely control the distance between the film and the core, ensuring stable, high-quality winding across different film thicknesses.

Applicable to Wide Range of Film Thickness :

For extra-thick films, the gap prevents slippage, ensuring film winding quality. On the other hand, for thinner films it avoids excessive compression, maintaining product integrity and uniformity. This feature makes the Sid Freedom Series an ideal choice in the market demanding film with the wide range of thickness.

Precision Control for Enhanced Quality :

The Sid Freedom Series is equipped with a high-precision control system that ensures winding stability and consistent tension, preventing film misalignment or deformation. Regardless of film thickness, the system guarantees stable tension and winding quality, furthermore, improves product consistency. Thanks to these features, the Sid Freedom Series stand out from multifunctional and high-precision film winding market.

Inquiry Form

Find HT representatives of your region

Fields marked with an asterisk * are required.