HT-VAL

LDPE blown film machine, HDPE blown film machine, Monolayer blown film machine, ABA blown film machine, Multilayer blown film machine

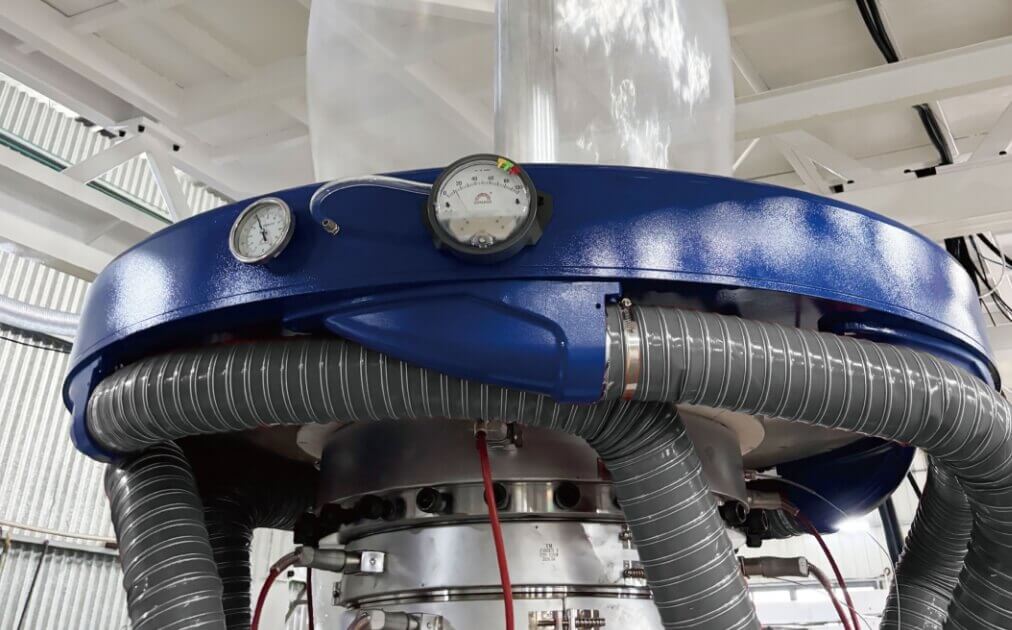

HT-VAL Line is devised based on the perspective of blown film manufacturers. This blown film production line with sufficient output and satisfying quality is designed for the users who look for the optimal specification of the machine with a limited budget. When we adopt each component of the machine, priority is to provide the simplest operation process and durable machine. The durability and power-saving specification allow customers to manage the blown film plant without worries.

How did Horng Tair achieve this difficult job to make this cost-effective blown film machine? In these 30 and more years, we’ve listened to a lot of voices from customers that they want a blown film line which is affordable and at the same time economical and durable when they operate it. It needs enough experience and expertise to choose the right components and design the machine structure. For example, lots of machines use small motors to reduce the cost, but too small motors would be broken soon after few months or years of operation. This would cost more than buying a bigger motor at once. With enormous experiences in the field, Horng Tair’s engineers would advise you to use the most efficient motor for your demanded specification. And also they calculate reduction rate of the gear box precisely, so that the extruder has the most efficient torque and rpm figures. With the suitable motor and gearbox, the machine’s efficiency and durability improve remarkably.

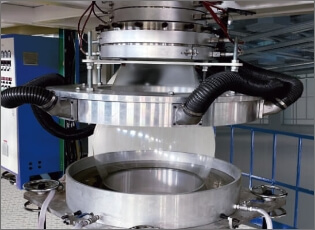

Moreover, because Horng Tair designs its own die heads, screws, and air ring, all the parts are well integrated. Among blown film line parts, there is no absolutely right design. Excellent screws also cannot provide a good performance if it doesn’t have a suitable die head and air ring for it. Die heads also as well. HT-VAL line concerns this interconnection of each part, so that Horng Tair customized blown film lines can meet customers’ various levels of demand.

How did Horng Tair achieve this difficult job to make this cost-effective blown film machine? In these 30 and more years, we’ve listened to a lot of voices from customers that they want a blown film line which is affordable and at the same time economical and durable when they operate it. It needs enough experience and expertise to choose the right components and design the machine structure. For example, lots of machines use small motors to reduce the cost, but too small motors would be broken soon after few months or years of operation. This would cost more than buying a bigger motor at once. With enormous experiences in the field, Horng Tair’s engineers would advise you to use the most efficient motor for your demanded specification. And also they calculate reduction rate of the gear box precisely, so that the extruder has the most efficient torque and rpm figures. With the suitable motor and gearbox, the machine’s efficiency and durability improve remarkably.

Moreover, because Horng Tair designs its own die heads, screws, and air ring, all the parts are well integrated. Among blown film line parts, there is no absolutely right design. Excellent screws also cannot provide a good performance if it doesn’t have a suitable die head and air ring for it. Die heads also as well. HT-VAL line concerns this interconnection of each part, so that Horng Tair customized blown film lines can meet customers’ various levels of demand.

# The specifications below would be changed according to design requirements.

Consumable Packaging

• Application description - Trash can liner, trash bag, kitchen bag, compost bag, flexible packaging, carrier bag

• Layer range - 1 ~ 3 layers

• Thickness range - 12 ~ 75 µm

• Output range - 200 ~ 900 kg /hr

• Production line speed - 120 m/min

• Layer range - 1 ~ 3 layers

• Thickness range - 12 ~ 75 µm

• Output range - 200 ~ 900 kg /hr

• Production line speed - 120 m/min

Industrial Films & Bags

• Application description - Industrial packaging, jumbo bag, pallet cover, also can be folded on line with a folding equipment

• Layer range - 1 ~ 3 layers

• Thickness range - 20 ~ 300 µm

• Output range - 250 ~ 850 kg /hr

• Production line speed - 100 m/min

• Layer range - 1 ~ 3 layers

• Thickness range - 20 ~ 300 µm

• Output range - 250 ~ 850 kg /hr

• Production line speed - 100 m/min

Lamination Film

• Application description - Dry lamination, wet lamination, paper lamination, metallic lamination (metalized film), adhesive lamination.

• Layer range - 1 ~ 5 layers

• Output range - 100 ~ 500kg /hr

• Production line speed - 120 m/min

• Layer range - 1 ~ 5 layers

• Output range - 100 ~ 500kg /hr

• Production line speed - 120 m/min

Agricultural & Membrane Film

• Application description - Mulching film, greenhouse film, pond liner, reflective film, greenhouse film, bale wrap film. Agricultural film can have embossing or smooth surface, also it can be folded on the line.

• Layer range - 3 ~ 7 layers

• Thickness range - 30 ~ 300µm

• Output range - 300 ~ 900 kg /hr

• Production line speed - 100 m/min

• Layer range - 3 ~ 7 layers

• Thickness range - 30 ~ 300µm

• Output range - 300 ~ 900 kg /hr

• Production line speed - 100 m/min

Shrink Film

• Application description - It is mainly used to produce shrink packaging films, which can be used in the packaging of food, beverages, medicines, daily necessities, etc. It has high transparency, high shrinkage and excellent heat sealing performance.

• Layer range - 1 ~ 5 layers

• Thickness range - 0.015 - 0.2 mm

• Output range - 10 - 350 kg/hr

• Production line speed - 10 - 120 m/min

• Suitable materials - PE (LDPE, LLDPE), PP, EVA, etc, and also other modified polyolefin materials.

• Layer range - 1 ~ 5 layers

• Thickness range - 0.015 - 0.2 mm

• Output range - 10 - 350 kg/hr

• Production line speed - 10 - 120 m/min

• Suitable materials - PE (LDPE, LLDPE), PP, EVA, etc, and also other modified polyolefin materials.

Stretch Films

• Application description - Packaging of goods with irregular shape

• Layer range - 1 ~ 7 layers

• Thickness range - 15 ~ 38 µm

• Output range - 750 - 900 kg /hr

• Suitable materials - LD, LLD, mLLD, EVA, etc.

• Layer range - 1 ~ 7 layers

• Thickness range - 15 ~ 38 µm

• Output range - 750 - 900 kg /hr

• Suitable materials - LD, LLD, mLLD, EVA, etc.

Your Application

We provide customized production line according to your application.

Inquiry Form

Find HT representatives of your region

Fields marked with an asterisk * are required.