HT-PRO

Multilayer blown film machine, PA barrier film extrusion machine, EVOH barrier film extrusion machine

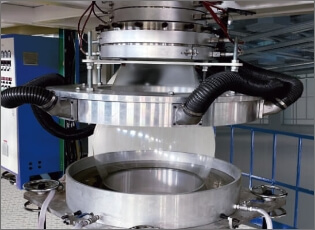

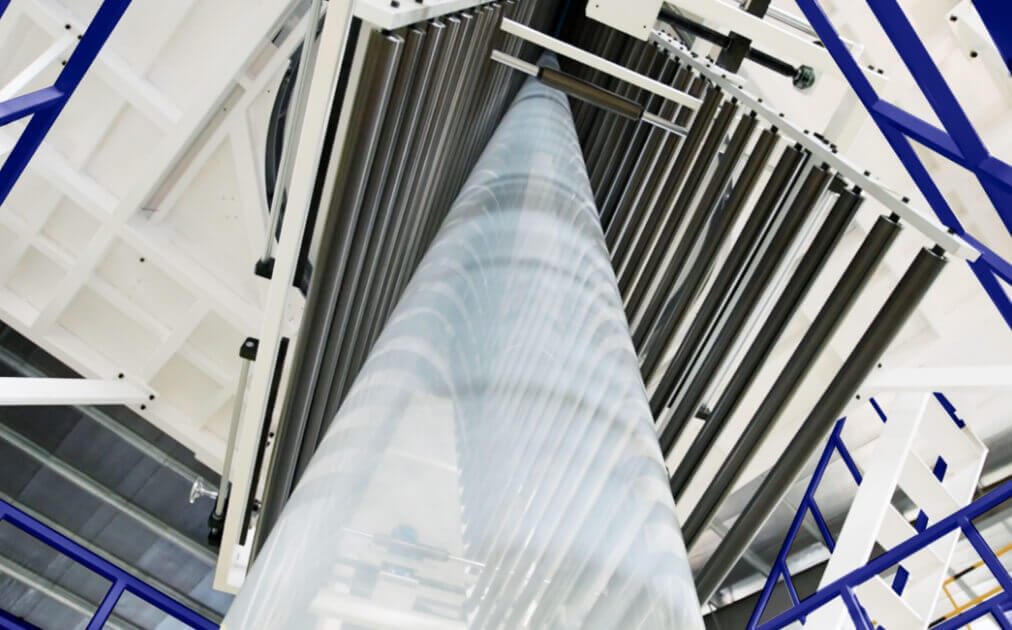

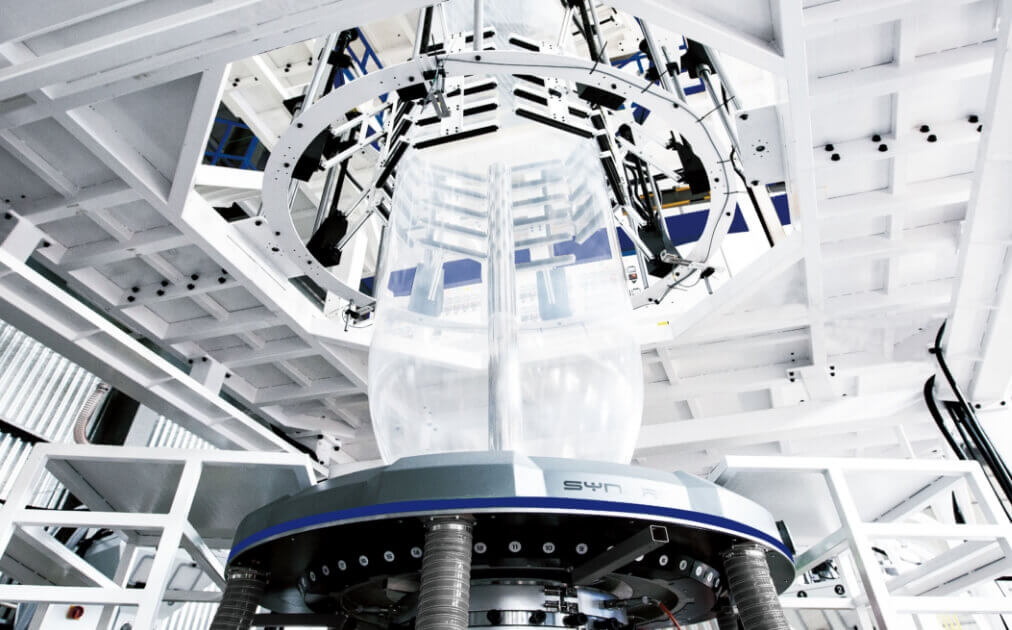

HT-PRO line is suitable for film manufacturer who is eager for higher quality and higher production capacity. By using automated system, consuming of raw materials will be more economical. Auto air-ring, auto dosing unit, auto bubble cage, IBC(Inner Bubble Cooling), auto winder and tension control system will let your operation highly automated.

Among this automatic system, auto air-ring is the main actor. You will see that when you operate the blown film machine with auto air ring, you will see not just better film flatness, but also that the time taken till the bubble arrive your required thickness and width will be shorten a lot. Using IBC and auto air-ring would also increase the output a lot as the cooling capacity increases. Many operation steps such as changing the winding roll would be safer and automated, therefore the working environment would be much more convenient and safer.

Sid Freedom winder series which has three(friction winding, center winding, and gap winding) mode in one winder(three-in-one) can be an option for the user who wants wide range of product, from the thinnest film to the thickest film, from hard film to soft film. The entire production line can be customized according to needs of customers.

Barrier film line is one of Sid's best-selling models. Less using barrier property materials(PA, EVOH etc.) and getting high barrier property is a goal for every barrier film manufacturers. It will come true with Sid's barrier film line, which has the most efficient screw and die head structure for EVOH and PA. Our barrier layer flow channel design is focused on the well distributed barrier layer and preventing degradation of the thermal sensitive material.

Horng Tair has significant experience and unique insights about plastic melt control within the die and screw. Our die-heads and screws are designed according to your demands, so if you have some special demands on the proportion or output of each layer, we can design flow channel exactly fits your requirements.

Among this automatic system, auto air-ring is the main actor. You will see that when you operate the blown film machine with auto air ring, you will see not just better film flatness, but also that the time taken till the bubble arrive your required thickness and width will be shorten a lot. Using IBC and auto air-ring would also increase the output a lot as the cooling capacity increases. Many operation steps such as changing the winding roll would be safer and automated, therefore the working environment would be much more convenient and safer.

Sid Freedom winder series which has three(friction winding, center winding, and gap winding) mode in one winder(three-in-one) can be an option for the user who wants wide range of product, from the thinnest film to the thickest film, from hard film to soft film. The entire production line can be customized according to needs of customers.

Barrier film line is one of Sid's best-selling models. Less using barrier property materials(PA, EVOH etc.) and getting high barrier property is a goal for every barrier film manufacturers. It will come true with Sid's barrier film line, which has the most efficient screw and die head structure for EVOH and PA. Our barrier layer flow channel design is focused on the well distributed barrier layer and preventing degradation of the thermal sensitive material.

Horng Tair has significant experience and unique insights about plastic melt control within the die and screw. Our die-heads and screws are designed according to your demands, so if you have some special demands on the proportion or output of each layer, we can design flow channel exactly fits your requirements.

# The specifications below would be changed according to design requirements.

Barrier Film

• Application description - Symmetrical and asymmetrical barrier film.

• Layer range - 5 ~ 9 layers

• Thickness range - 20 ~ 200 µm

• Output range - 200 ~ 550 kg /hr

• Suitable materials - LD, LLD, EVA, EVOH, PA, PP, lonomer, Tie, etc.

• Layer range - 5 ~ 9 layers

• Thickness range - 20 ~ 200 µm

• Output range - 200 ~ 550 kg /hr

• Suitable materials - LD, LLD, EVA, EVOH, PA, PP, lonomer, Tie, etc.

Lamination Film

• Application description - Dry lamination, wet lamination, paper lamination, metallic lamination (metalized film), adhesive lamination.

• Layer range - 3 ~ 5 layers

• Output range - 300 ~ 500kg/hr

• Production line speed - 120 m/min

• Layer range - 3 ~ 5 layers

• Output range - 300 ~ 500kg/hr

• Production line speed - 120 m/min

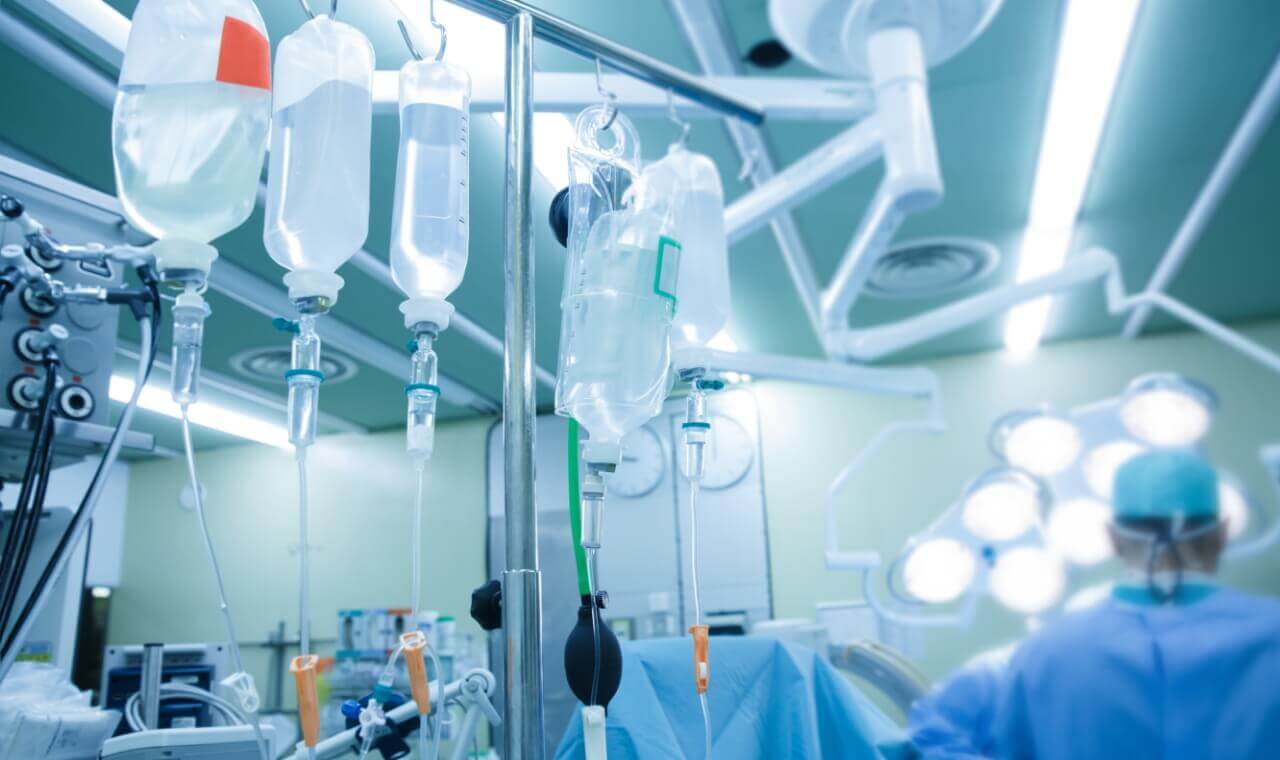

Medical Film

• Application description - Medical application of blown film is infusion bag, film that used in cleanroom, etc. These medical films need special optical properties(transparancy and gloss), excellent softness and elasticity and low volatility.

• Layer range - 3 ~ 7 layers

• Thickness range - 40 ~ 800µm

• Output range - 50 ~ 550 kg /hr

• Production line speed - 20 ~ 100m/min

• Suitable materials - PE, PP, EVOH, PVDC/PVC, EVA, EMA, TPU, etc, and also other polyolefin materials

• Layer range - 3 ~ 7 layers

• Thickness range - 40 ~ 800µm

• Output range - 50 ~ 550 kg /hr

• Production line speed - 20 ~ 100m/min

• Suitable materials - PE, PP, EVOH, PVDC/PVC, EVA, EMA, TPU, etc, and also other polyolefin materials

Agricultural & Membrane Film

• Application description - Silage film, pond liner, geomembrane film, mulching film, reflective film, greenhouse film, bale wrap film. Agricultural film can have embossing or smooth surface, also it can be folded on the line.

• Layer range - 3 ~ 7 layers

• Thickness range - 30 ~ 300 µm

• Output range - 200 ~ 900 kg /hr

• Production line speed - 100 m/min

• Layer range - 3 ~ 7 layers

• Thickness range - 30 ~ 300 µm

• Output range - 200 ~ 900 kg /hr

• Production line speed - 100 m/min

Your Application

We provide customized production line according to your application.

Inquiry Form

Find HT representatives of your region

Fields marked with an asterisk * are required.