HT-LAB

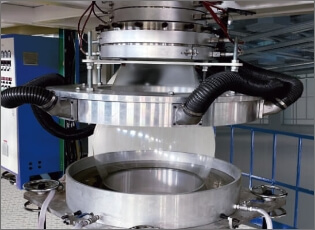

PE experimental blown film machine, TPU experimental blown film machine, Multilayer labscale blown film machine.

HT-LAB line is experimental blown film machine which specifically designed for researching and developing new manufacturing processes. It is compact, multipurpose, and provides an economical and efficient way to test the feasibility of new product lines and materials. Test results from this lab-scale blown film machine can help predict performance in large-scale production, ensuring that products meet demanded quality and efficiency before entering mass production.

This laboratory blown film line is also ideal for handling small batch orders with frequent product changes. It can quickly switch between different production requirements, enhancing manufacturing flexibility and helping your factory increase competitiveness and profitability in diverse markets.

Key Functionalities of the Experimental Blown Film Machine

Testing New Products and Materials

HT-LAB allows experiment to blow various material of film to assess suitability and feasibility of new material. Simulating blown film process for new product designs with laboratory blown film machine and to confirm durability, molding quality, and production feasibility.

Small-Batch Production

HT-LAB suits customers who want to adapt rapidly changing market demands, supporting flexible small-batch production. Reducing switch-over time in cases of frequent product changes will let you improve production efficiency and reducing costs.

Technical and Process Optimization

HT-LAB enables optimization of blown film extrusion process parameters, including temperature, pressure, and cooling. Also this experimental blown film line will assists your R&D teams to enhance the stability and precision of the blown film process, reducing errors and defect rates in mass production.

Production Line Transition Simulation

HT-LAB simulates small-scale test results to estimate performance on large-scale blown film production lines. Also, it will help you minimizing potential risks during production transitions, lowering start-up costs.

Operation and Training Applications

HT-LAB provides an easy-to-use interface suitable for training technical staff within the company. Through experimental blown film operations, your technical team can build the experience and skill, strengthening their professional capabilities.

The laboratory blown film extrusion machine is a highly flexible and cost-effective testing tool, ideal for developing a new product, innovating process of manufacturing film, and small-batch production. It effectively supports blown film factory in maintaining competitive edge on competitors in the market while improving production efficiency and profitability. Make your best choice for new product development and application of new materials!

This laboratory blown film line is also ideal for handling small batch orders with frequent product changes. It can quickly switch between different production requirements, enhancing manufacturing flexibility and helping your factory increase competitiveness and profitability in diverse markets.

Key Functionalities of the Experimental Blown Film Machine

Testing New Products and Materials

HT-LAB allows experiment to blow various material of film to assess suitability and feasibility of new material. Simulating blown film process for new product designs with laboratory blown film machine and to confirm durability, molding quality, and production feasibility.

Small-Batch Production

HT-LAB suits customers who want to adapt rapidly changing market demands, supporting flexible small-batch production. Reducing switch-over time in cases of frequent product changes will let you improve production efficiency and reducing costs.

Technical and Process Optimization

HT-LAB enables optimization of blown film extrusion process parameters, including temperature, pressure, and cooling. Also this experimental blown film line will assists your R&D teams to enhance the stability and precision of the blown film process, reducing errors and defect rates in mass production.

Production Line Transition Simulation

HT-LAB simulates small-scale test results to estimate performance on large-scale blown film production lines. Also, it will help you minimizing potential risks during production transitions, lowering start-up costs.

Operation and Training Applications

HT-LAB provides an easy-to-use interface suitable for training technical staff within the company. Through experimental blown film operations, your technical team can build the experience and skill, strengthening their professional capabilities.

The laboratory blown film extrusion machine is a highly flexible and cost-effective testing tool, ideal for developing a new product, innovating process of manufacturing film, and small-batch production. It effectively supports blown film factory in maintaining competitive edge on competitors in the market while improving production efficiency and profitability. Make your best choice for new product development and application of new materials!

Inquiry Form

Find HT representatives of your region

Fields marked with an asterisk * are required.