HT-AQUA

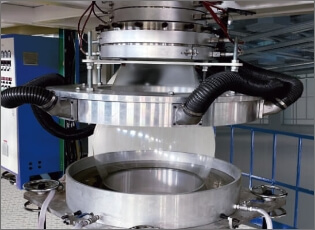

Monolayer PP blown film machine, Multilayer PP blown film machine, Water cooling PA blown film machine.

HT-AQUA line adopts advanced top-down extrusion technology and uses water as the heat transfer medium to achieve efficient and rapid cooling during the process, bringing excellent transparency and strength to blown film products. Water cooling blown film lines have a wide range of applications, and the most common model is PP blown film machine. The common translucent clothing packaging and food packaging films in our daily life are PP blown films. PP blown film has good rigidity and transparency, so it can be widely used in packaging films for various products. The multilayer water-cooled blown film production line can also produce barrier films for medical infusion bags and food packaging.

Rapid water cooling : In the typical air cooling blown film line, the cooling speed is slow and there would form a lot of plastic crystal. The design of the down forward type blown film machine allows the film to be extruded from above and directly enter the water-cooling unit, shortening the distance from forming to cooling. The efficient heat conduction characteristics of water are used to quickly cool down the film in a short time. This process extremely suppresses the growth of crystal, greatly improves the transparency and surface smoothness of the blown film product, and meets the market demand for extremely high requirement of appearance properties.

Enhanced puncture and tear resistance : In addition to improving transparency, water cooling technology also strengthens the internal structure of the film, giving it excellent puncture and tear resistance. This means that the finished blown film not only has good appearance, but also has durability and can deal with more harsh environments when it is used.

Generally speaking, the water-cooled film blowing machine, with its efficient cooling performance and advanced extrusion technology, provides users with blown film products with excellent transparency and strong damage resistance, making it an ideal choice for various packaging applications.

Rapid water cooling : In the typical air cooling blown film line, the cooling speed is slow and there would form a lot of plastic crystal. The design of the down forward type blown film machine allows the film to be extruded from above and directly enter the water-cooling unit, shortening the distance from forming to cooling. The efficient heat conduction characteristics of water are used to quickly cool down the film in a short time. This process extremely suppresses the growth of crystal, greatly improves the transparency and surface smoothness of the blown film product, and meets the market demand for extremely high requirement of appearance properties.

Enhanced puncture and tear resistance : In addition to improving transparency, water cooling technology also strengthens the internal structure of the film, giving it excellent puncture and tear resistance. This means that the finished blown film not only has good appearance, but also has durability and can deal with more harsh environments when it is used.

Generally speaking, the water-cooled film blowing machine, with its efficient cooling performance and advanced extrusion technology, provides users with blown film products with excellent transparency and strong damage resistance, making it an ideal choice for various packaging applications.

# The specifications below would be changed according to design requirements.

Food Packaging

• Application description - Vacuum skin packaging, lamination film.

• Layer range - 1 ~ 9 layers

• Thickness range - 25 ~ 250 µm

• Suitable materials - LDPE, LLDPE, HDPE, EPE, PA, EVOH, EVA, PP, PETG, Ionomers, plastomers, etc.

• Layer range - 1 ~ 9 layers

• Thickness range - 25 ~ 250 µm

• Suitable materials - LDPE, LLDPE, HDPE, EPE, PA, EVOH, EVA, PP, PETG, Ionomers, plastomers, etc.

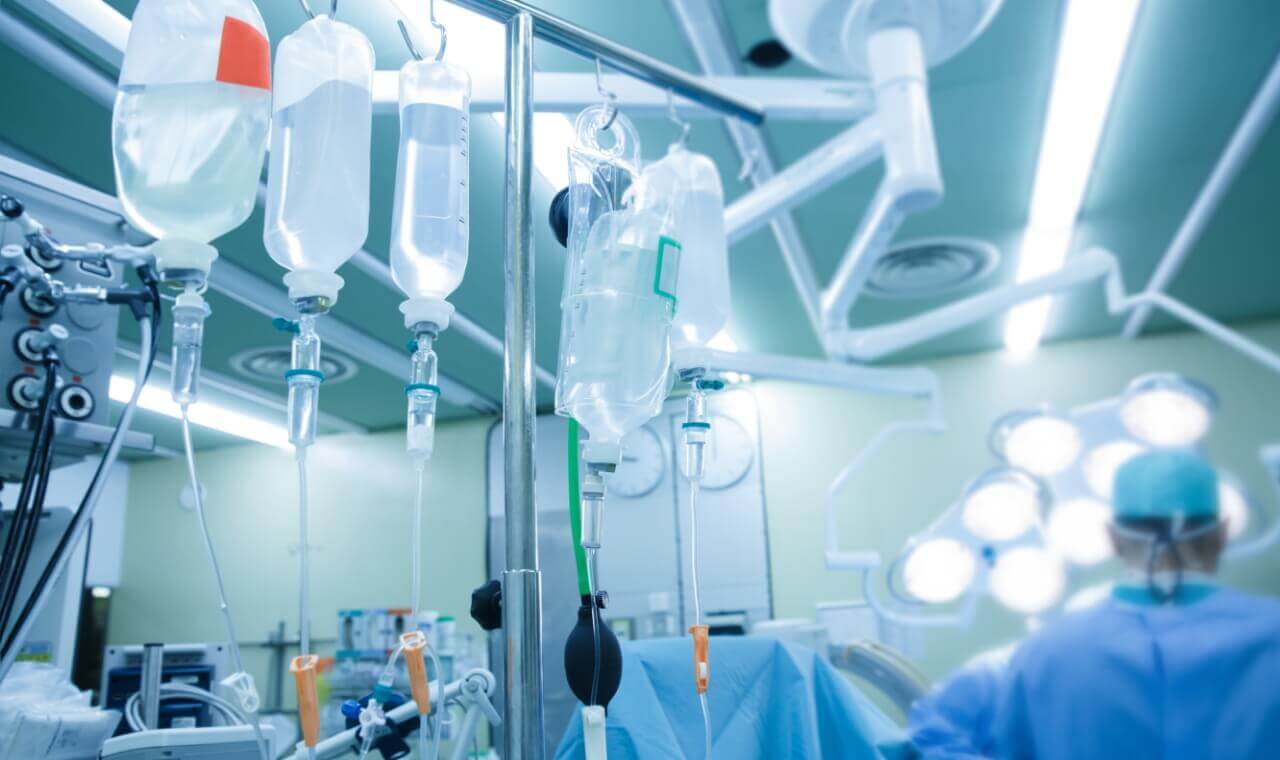

Medical Film

• Application description - Medical application of blown film is infusion bag, film that used in cleanroom, etc. These medical films need special optical properties(transparency and gloss), excellent softness and elasticity and low volatility.

• Layer range - 3 ~ 7 layers

• Thickness range - 40 ~ 800µm

• Output range - 50 ~ 300 kg /hr

• Production line speed - 20 ~ 100m/min

• Suitable materials - PE, PP, EVOH, PVDC/PVC, EVA, EMA, etc.

• Layer range - 3 ~ 7 layers

• Thickness range - 40 ~ 800µm

• Output range - 50 ~ 300 kg /hr

• Production line speed - 20 ~ 100m/min

• Suitable materials - PE, PP, EVOH, PVDC/PVC, EVA, EMA, etc.

Industrial Films & Bags

• Application description - Industrial packaging.

• Layer range - 1 ~ 5 layers

• Thickness range - 20 ~ 300µm

• Output range - 250 ~ 850 kg /hr

• Production line speed - 100 m/min

• Layer range - 1 ~ 5 layers

• Thickness range - 20 ~ 300µm

• Output range - 250 ~ 850 kg /hr

• Production line speed - 100 m/min

Shrink Film

• Application description - It is suitable for making shrink film products that require high transparency and uniform thickness. It is mainly used for quick packaging of food, beverages, medicine, etc. It has good size stability and shrinkage.

• Layer range - 1 - 5 layers

• Thickness range - 0.01 - 0.1 mm

• Output range - 15 - 100 m/min

• Production line speed - 100 m/min

• Suitable materials - PE(LDPE、LLDPE), PP, EVA, etc, and also other modified polyolefin materials.

• Layer range - 1 - 5 layers

• Thickness range - 0.01 - 0.1 mm

• Output range - 15 - 100 m/min

• Production line speed - 100 m/min

• Suitable materials - PE(LDPE、LLDPE), PP, EVA, etc, and also other modified polyolefin materials.

Your Application

We provide customized production line according to your application.

Inquiry Form

Find HT representatives of your region

Fields marked with an asterisk * are required.